Shroud Tube System

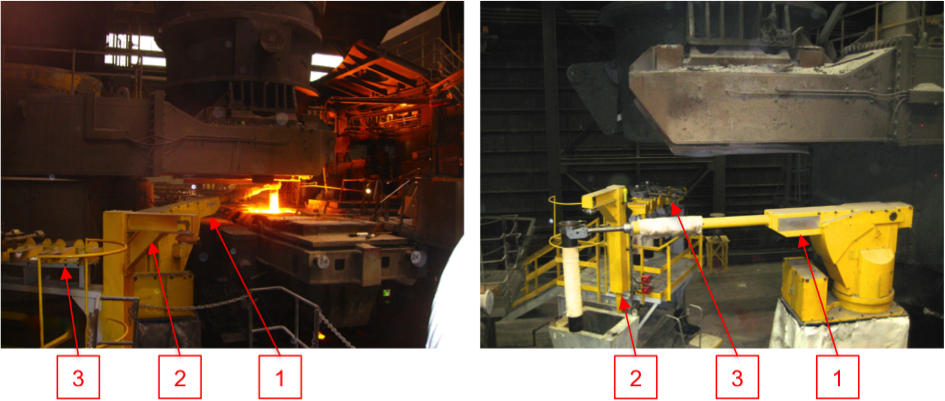

The shroud tube system is a very important part to guarantee best quality during continuous casting. It is installed between the foundry ladle and the steel cast distribution to the funnel of the casting tube. VeCon shroud tube systems are consisting of:

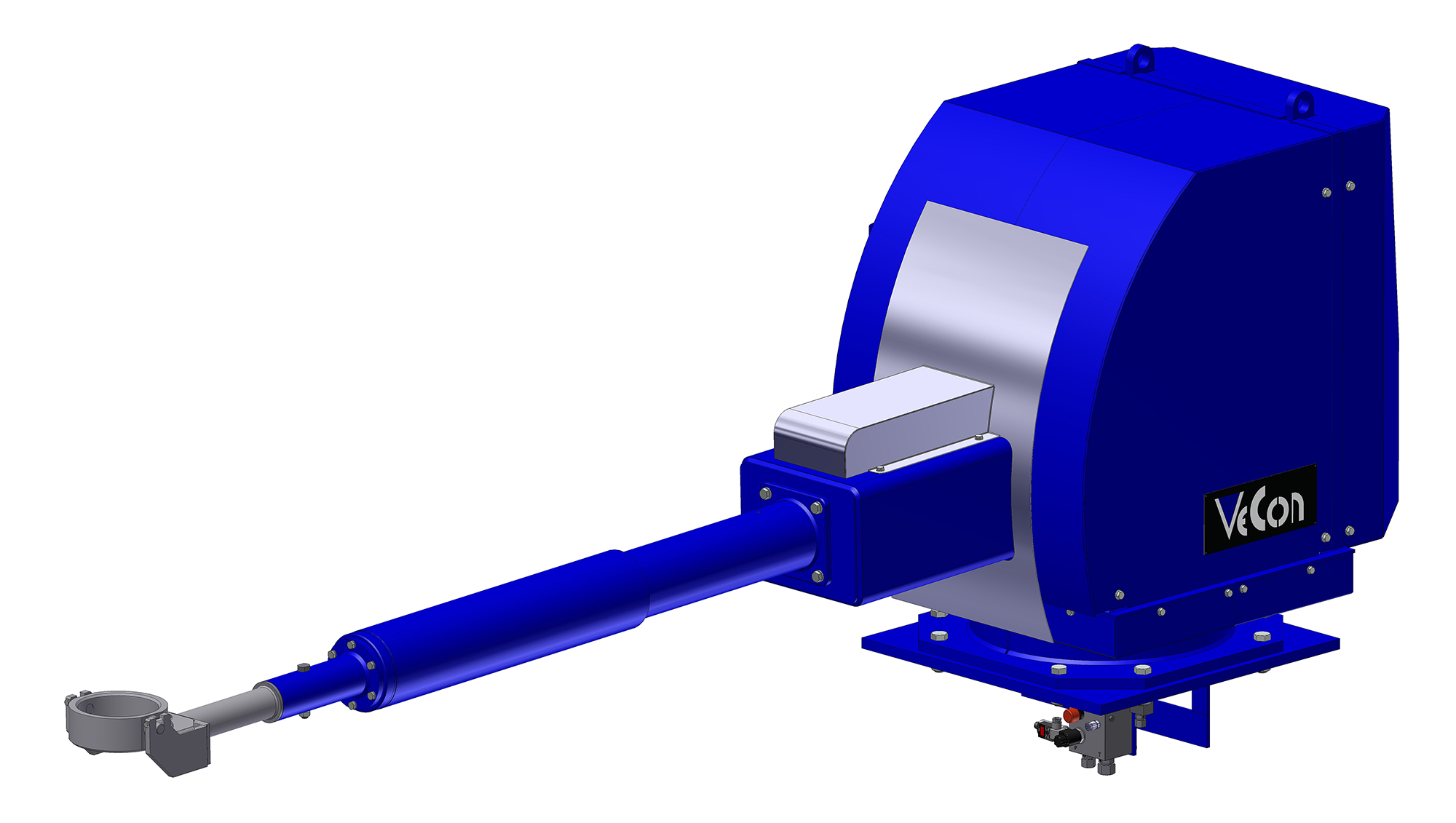

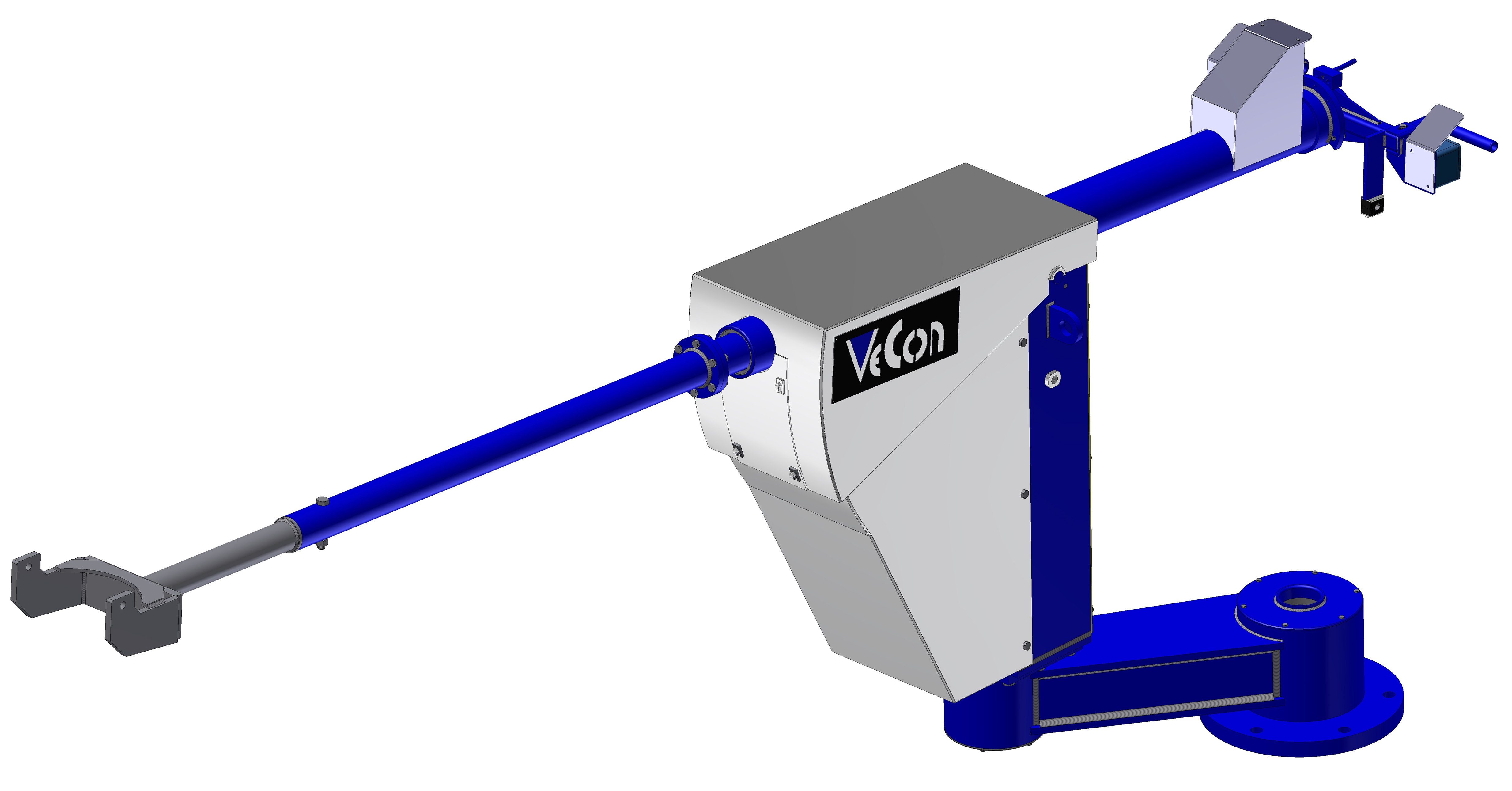

Shroud tube manipulator (1)

Burnout station (2)

Tube magazine (3)

Feeding of casting powder (not shown)

The shroud tube manipulator is forming a secure connection between shroud tube and ladle slide gate during casting. With the usage of a shroud tube manipulator, the quality of steel after casting and the safety of work increase. In addition, productivity is clearly improved because of shortened cycle times for shroud tube changes or tube cleaning (burn out station).

The shroud tube manipulator of VeCon will be offered in several versions. Due to the level of automation, VeCon offers semi-automatic and full-automatic manipulators.

There are different types of design are adapted according to customers’ demands and specifications and local conditions.

Please find detailed information about our manipulator types in our product sheets.

- Semi-automatic

- Pneumatic manipulator single (PMS) (DOWNLOAD)

- Hydraulic manipulator / pneumatic manipulator (HM/PM) (DOWNLOAD)

- Hydraulic electric manipulator / pneumatic electric manipulator (HEM/PEM) (DOWNLOAD)

- Full-automatic

- Hydraulic electric manipulator with remote control